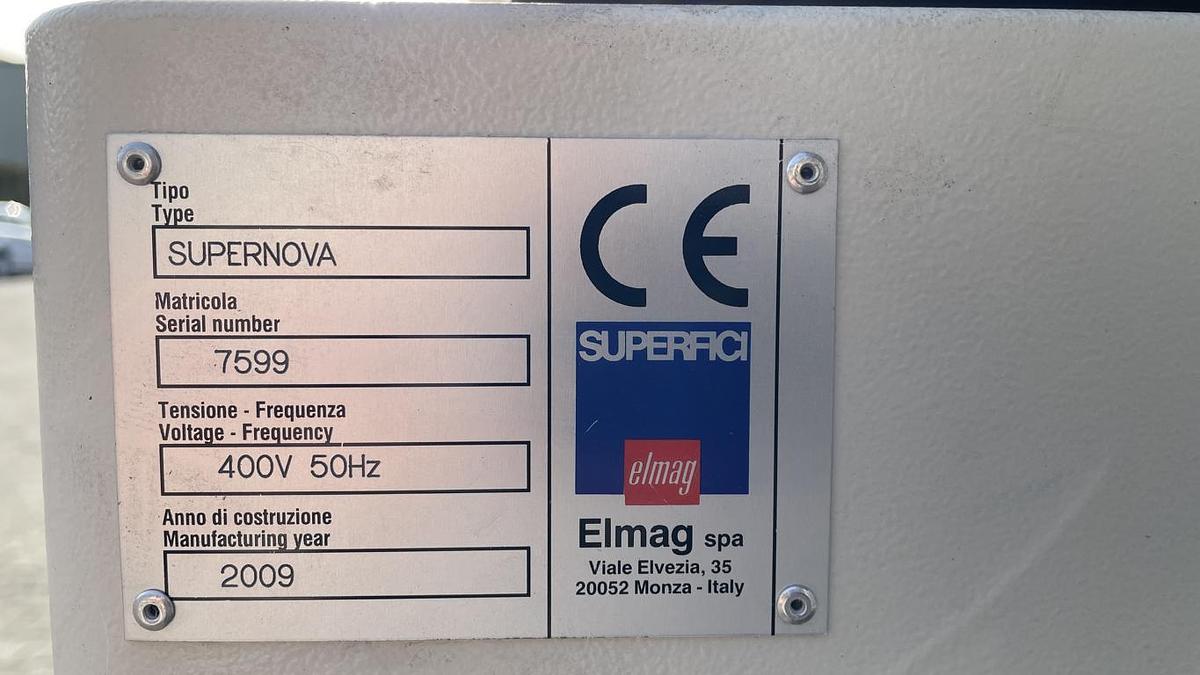

Superfici roller coating machine type SUPERNOVA, BEIZE

Sold

Superfici roller coating machine type SUPERNOVA, BEIZE

Location:Blomberg, Germany

Description

Rolling coating machine SUPERFICI

Type. Supernova

for the coating of pickling

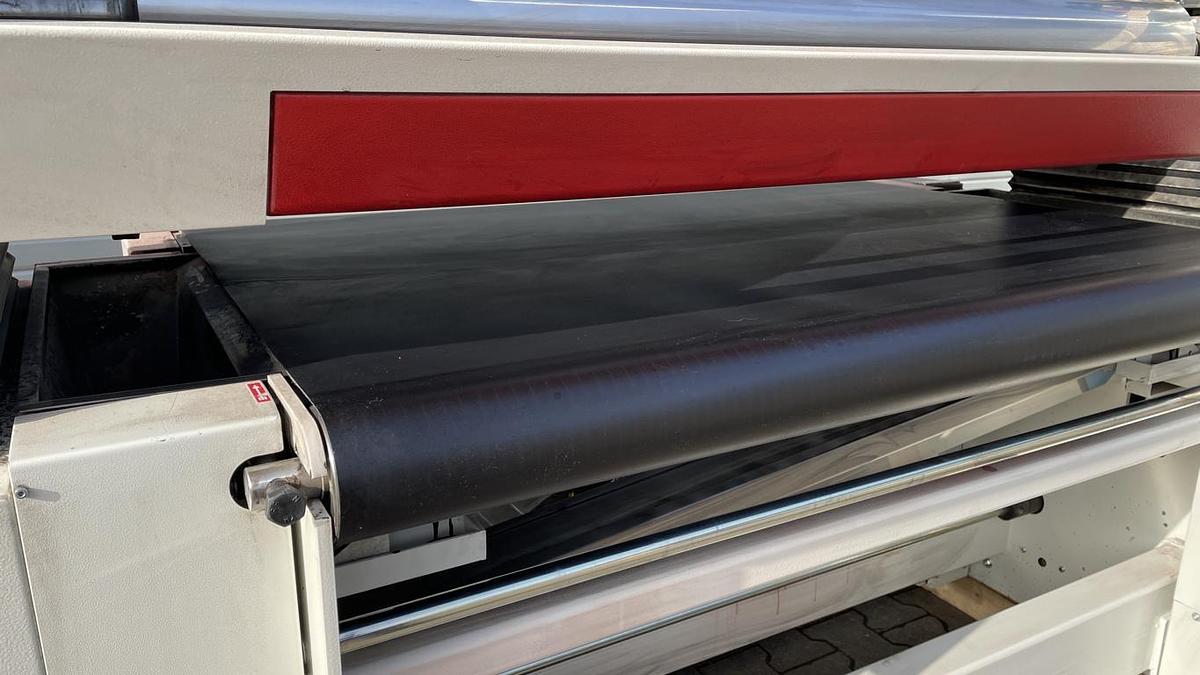

Base frame and conveyor system

Welded steel frame construction in modular design;

Conveyor system with standalone and removable base frame for easy maintenance.

Independent feed drive with frequency control.

Band centering and clamping device.

Solvent-resistant, non-slip conveyor belt.

Machine can be removed from the production line using rollers and floor rails for easy cleaning.

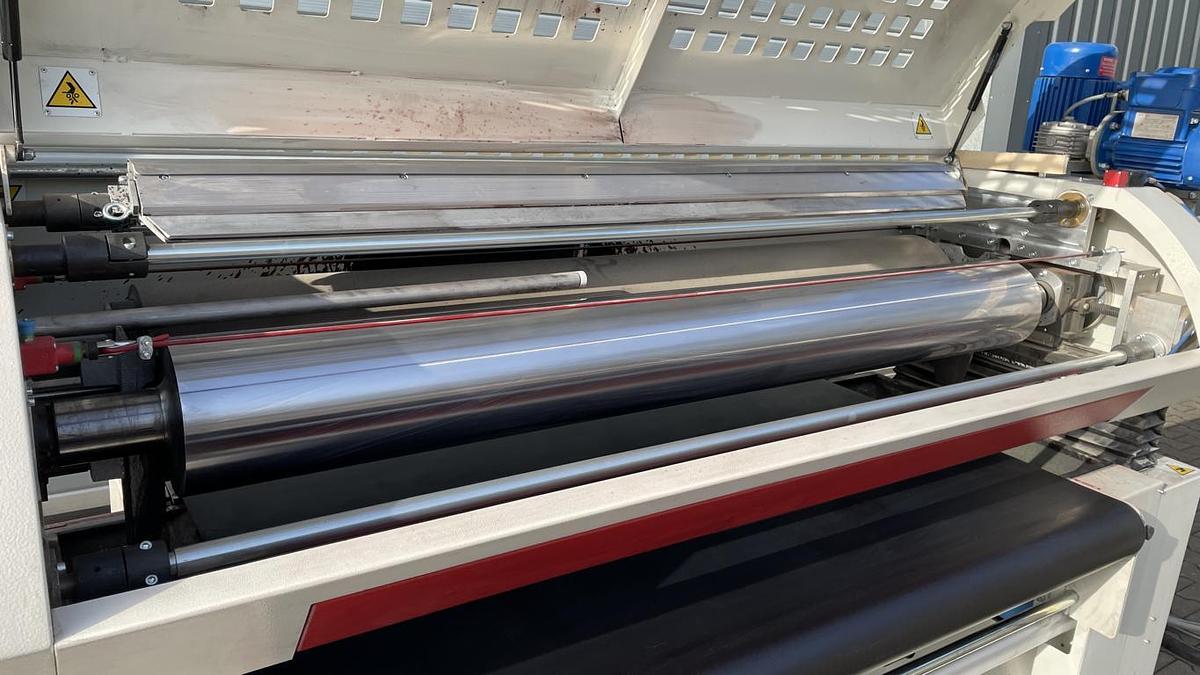

High-precision coating head

With independent, frequency-controlled drives for:

- rubber-coated coating roller; Moosgummi coating

- chrome-dosed roller.

High coating accuracy due to:

- height adjustment and setting the distance between

coating roller and dosing roller on high-precision linear guides with ball circulation system for smooth

and accurate movement.

- permanent monitoring of the working pressure at the coating head on

the workpieces via pneumatic cylinders. The pressure of the cylinders can be adjusted to achieve the

desired pressing force of the coating head depending on the workpiece and the type of coating

to be achieved.

- Independent movements by frequency-controlled drives

with bevel gear for coating roller, dosing roller and feed.

Ergonomic, fully openable protective covers on the coating head, for easy cleaning and maintenance.

Dosing roller with the possibility of reversible rotation direction.

Manual height adjustment of the working height with mechanical digital display.

Mechanical digital display for the distance between coating and dosing roller.

Pneumatic emergency lift of the coating head in case of line stop, to protect roller rubberization. (STANDARD)

Lacquer circuit

Pneumatic double-membrane pump for lacquer conveyance.

Stainless steel platform with two positions for lacquer containers.

Lacquer recycling system with double outlet to enable a quick switch between lacquer and solvent containers.

Machine cleaning cycle with automatic synchronization of speeds.

Rake completely pull-out on the side.

Lacquer troughs and side collection hoppers made of stainless steel are completely removable for easy cleaning.

Control

Control cabinet, mounted on the side opposite the machine operation side and connected to the machine frame.

Control panel on the machine with all components for setting and displaying operating speeds.

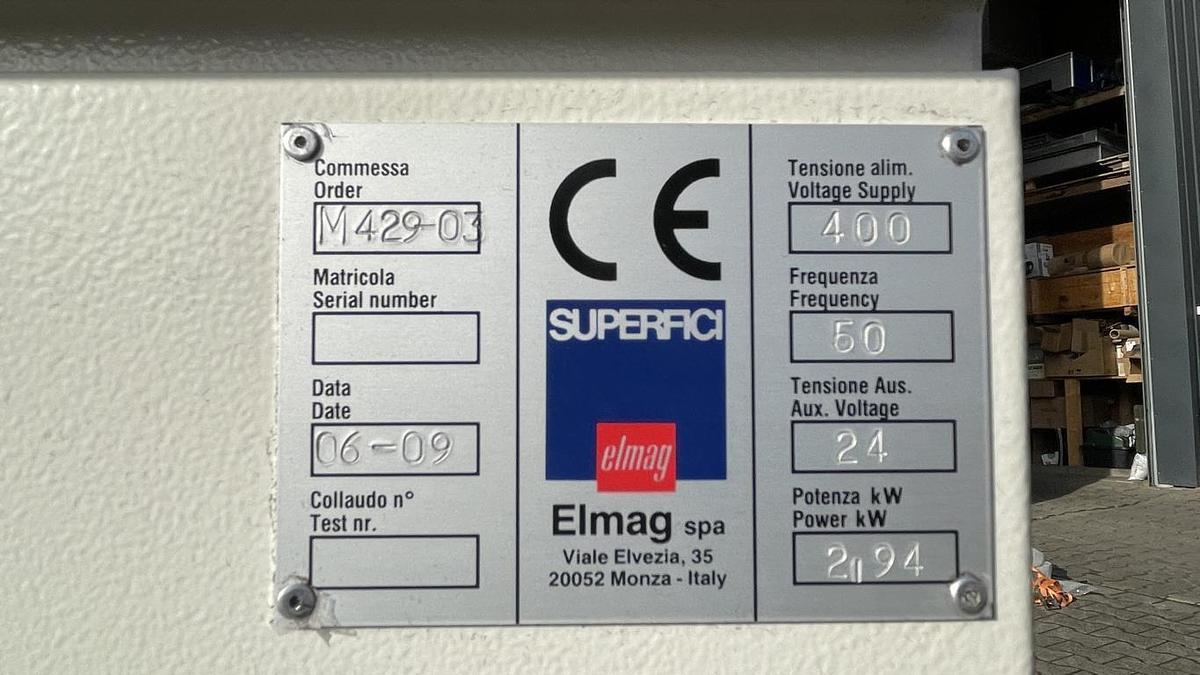

Machine built in accordance with CE standards, for use with non-flammable and non-explosive lacquers and for installation in safe zones (classified as non-explosive area)

Technical data:

Year of construction 2009

Web width: 1,370 mm

Machine length: 1,000 mm

Working height: 900 +/- 20 mm

Workpiece thickness: 3 120 mm

Diameter coating roller: 245 mm

Hardness of coating roller 30 Sh

Material of coating roller Moosgummi

Diameter dosing roller: 175 mm

Feed rate: 8 - 24 m/min

Compressed air consumption 25 Nl/min

Installed total electrical power: ca. 2 kW

Color: RAL 9002 gray

Operating side: left

Specifications

| Manufacturer | Kein Hersteller |

| Condition | Used |

| Stock Number | 3310923 |

| Item location | D - North Rhine-Westphalia |