Venjakob HGS/-Duo/C painting system, pallet conveyor

Sold

Venjakob HGS/-Duo/C painting system, pallet conveyor

Location:Blomberg, Germany

Description

consisting of:

- Automatic spray gun HGS - DUO/C

- Working width 1100 mm

- With pallet conveyor system

- exhaust channel

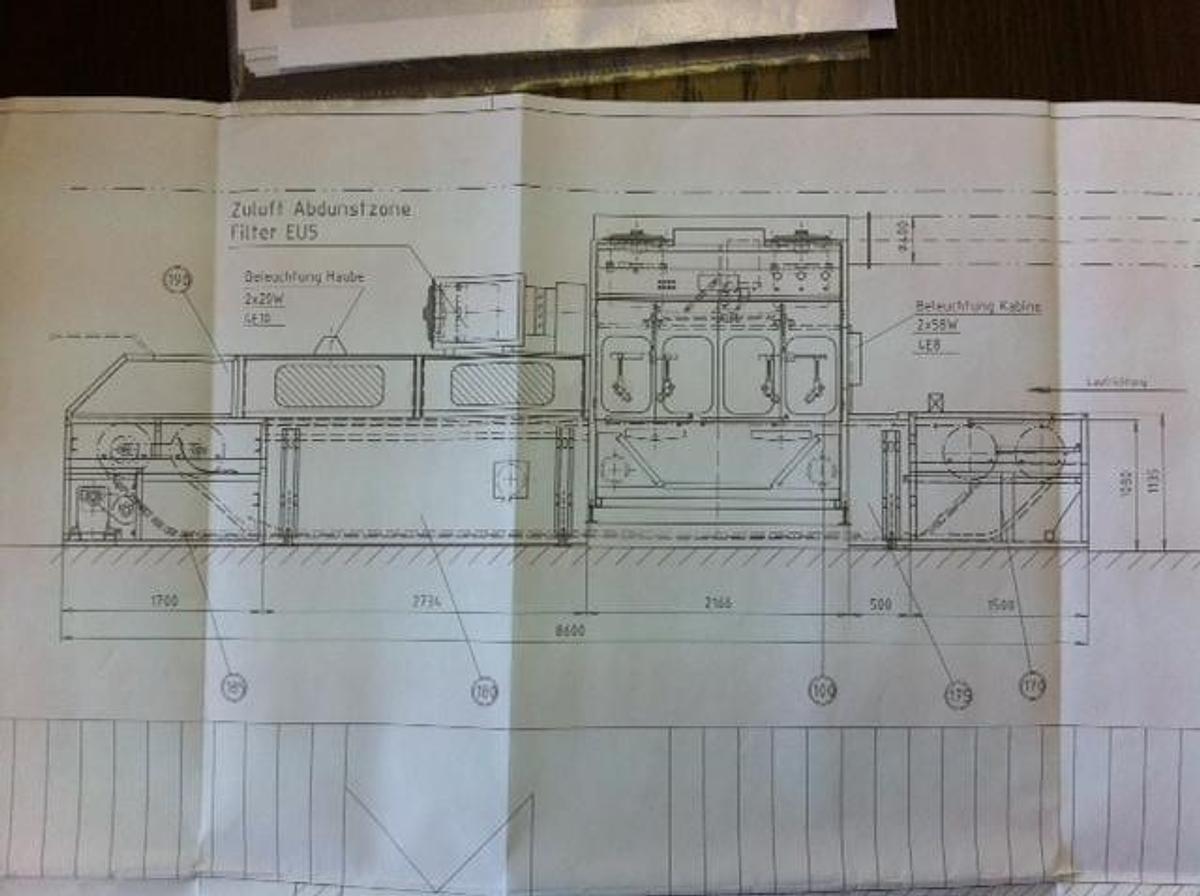

- Total length 8600 mm

- Year of construction 1999

Description of the individual assemblies:

SPRAYING MACHINE TYPE HGS-Z,

1 spray booth

Spray booth housing, manufactured in a stable profile element design as a bolted construction. On the operator side there are double folding doors with large viewing windows and electric door limit switches. On the opposite side to the operating side, the booth is equipped with inspection doors so that all areas of the booth are easily accessible. The spray area is illuminated by a fluorescent tube.

Above the folding doors there is a switch panel with all the control fittings required for operating the system, compressed air control fittings, pressure gauge, differential pressure monitor, gun test switch, push-button command group for all drive motors, including emergency stop button.

The electrical switching elements are wired to terminal boxes.

1 electrical control cabinet

With all necessary switching and fuse elements, motor protection switches, indicator lamps and main switch. All components are wired to terminals.

The control cabinet contains all the necessary contacts for interlocking the machine offered as well as third-party machines.

1 Gun drive Z

designed as a high-performance linear lifting unit with servo drive. The linear unit is fully enclosed. It consists of a low-wear linear guide unit made of machined extruded aluminum profile and hardened steel shafts. The carriage is driven by toothed belts and is made of torsion-resistant light metal with heavy-duty rollers mounted on roller bearings. The lubrication system is supplied via a central lubrication device installed on the operating side of the spray booth. The design guarantees a constant gun speed across the entire working width. The gun speed is infinitely variable from 0.4 - 2.5 m/sec. via PLC control unit on the control cabinet. (max. 30 double strokes). The deceleration and acceleration values automatically adapt to the selected gun speed. This produces a smooth gun movement in all speed ranges. It is driven by a servomotor.

All supply lines to the spray guns are routed in an energy supply chain. The various spray programs are set on the switch panel using a selector switch. Up to 15 individual programs can be saved.

The gun carrier is designed for a maximum of 8 spray guns. All spray guns are equipped with a ring flushing system for quick change of spray material. Each spray gun is equipped with height and angle adjustment.

1 pallet conveyor system

suitable for operation of the system by one person at the infeed of the machine,

with an upper forward transport level and a lower return transport level, consisting of transport pallets arranged close together. The conveyor base frame is made of sturdy bolted and welded sheet steel. Drive sprockets and pallet support discs are mounted on a central clamping plate and can be adjusted via threaded spindles. The pallets consist of a sturdy frame protected against spray mist.

Technical data:

- Length: 8726 mm

- Number of conveyor pallets: 20 pcs.

- Pallet dimensions: 730x1520 mm

- Working width: max. 1100 mm

- Feed speed: 0.5-2.5 m/min

1 suction system "TROCKEN

made of galvanized sheet steel,

consisting of:

2 suction shafts arranged transverse to the running direction with Andrea

paper filter in the insertion frame, can be pulled out to the operating side.

The extraction shafts are opposite the operating side and connected to

connected to a further filter system.

These filter elements are made of random fiber fleece and can also be

can also be pulled out to the side for cleaning purposes.

Cabin width: as per installation drawing

1 fan

for extracting the paint mist and exhaust air for the evaporation zone,

Air output: 10000 m3/h

1 gun control

via photocell before entering the spray booth by scanning the front and rear edges.

front and rear edges.

Guns are switched on and off in groups.

The spray width is set manually using adjustable initiators.

1 dust cover

at the outlet of the machine, can be folded up, with viewing windows

Length approx.: 1100 mm

1 supply air filter cover AV

fully integrated into the upper booth area for targeted guidance of the air flow

the air flow inside the spray booth from the air inlet ceiling

to the extraction shafts.

The individual filter elements are easy to replace.

The system consists of:

- 2 axial supply air fans with adjustable air volume

- 2 filter stages with regenerable EU3/5 filter elements

- 1 overpressure measuring device for monitoring the filter status.

1 exhaust duct

- not heated

- Length approx. 3500 mm

- with flap at the outlet, incl. EU5 supply air filter, supply air fan

- Supply and exhaust air volume: approx. 4000 m3/h

Specifications

| Manufacturer | Kein Hersteller |

| Condition | Used |

| Stock Number | 3301740 |

| Item location | D - North Rhine-Westphalia |