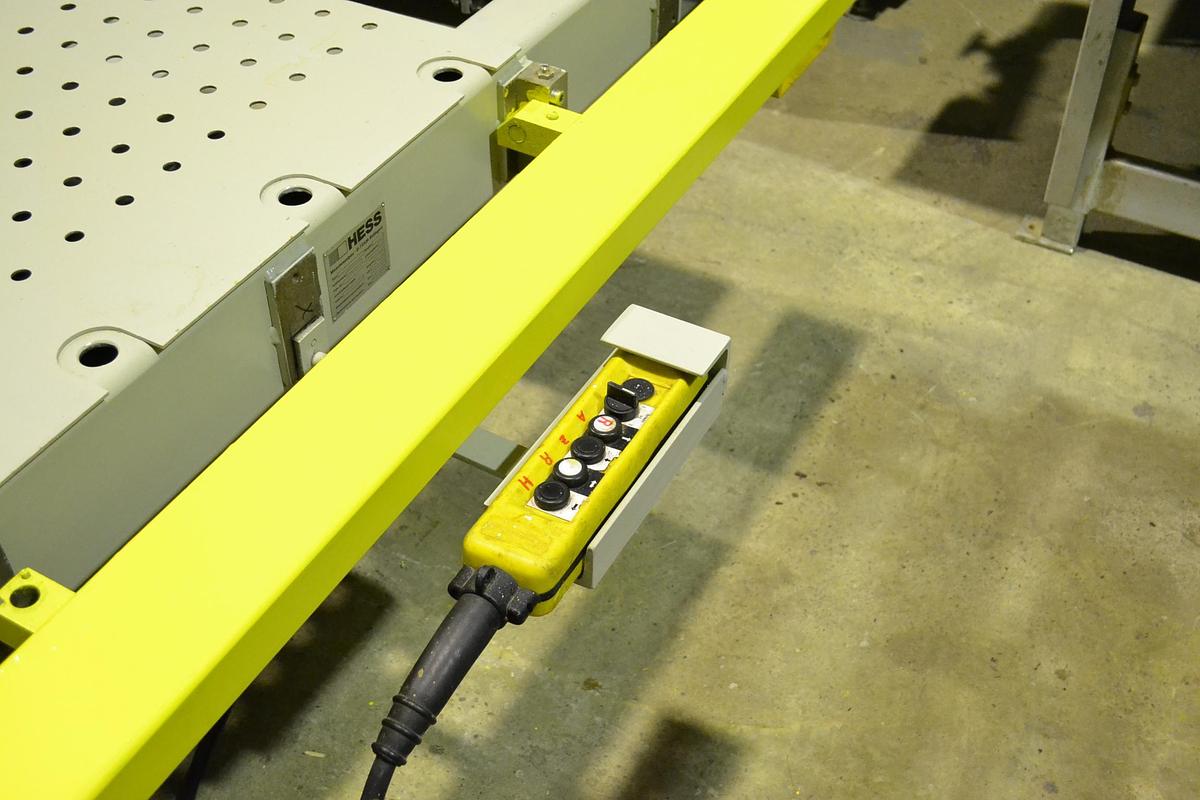

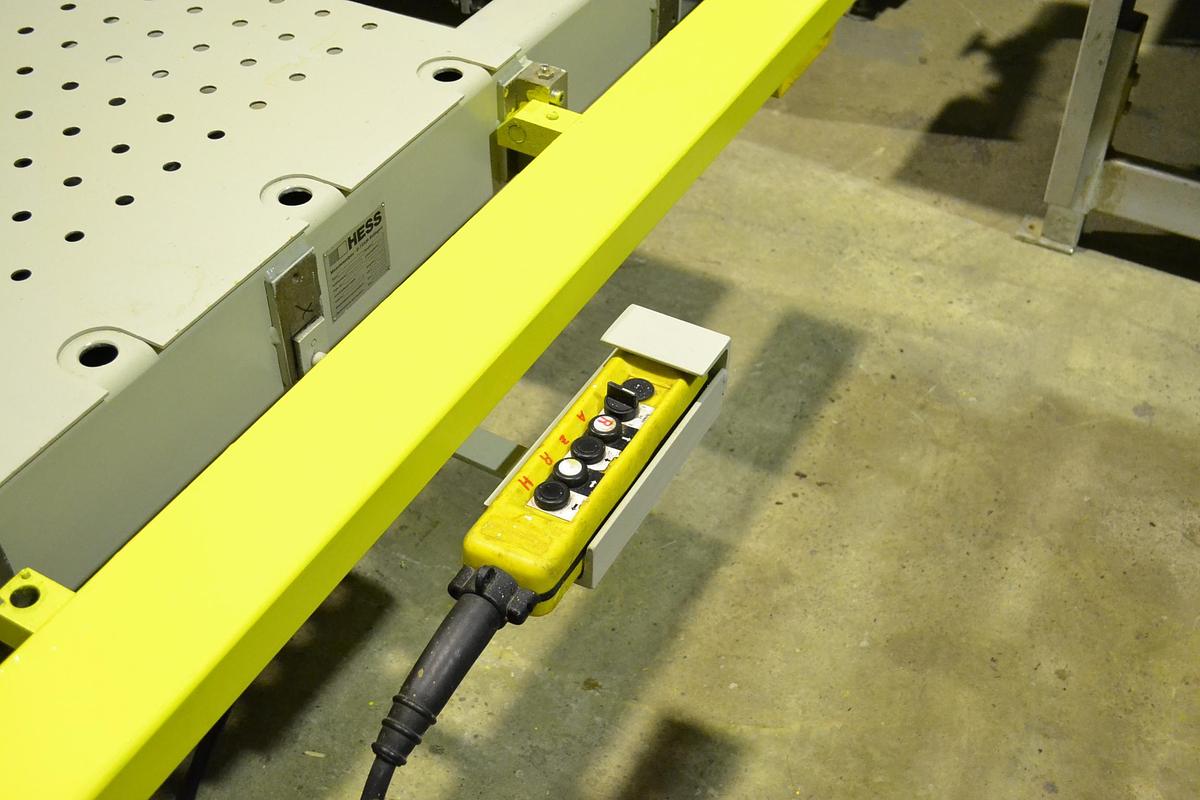

Assembly table HESS PRO LIGNO - LP 12500

Sold

Assembly table HESS PRO LIGNO - LP 12500

Location:Blomberg, Germany

Description

Overview of equipment:

- Standable

- 2 split pressing beams, motor-driven movable

- perforated sheet cladding

- 4 plug-in clamping cylinders

- 2 foldable stops on front edges

- 2 longitudinal U-profile guide rails

Description:

The variable mounting station, manufactured by HESS PRO LIGNO - LP 12500 for universal use in the assembly of single- or double-faced panelled wall, gable, roof and ceiling elements as well as knee supports in frame construction.

Heavy base frame of the machine frame for an absolutely flat work surface.

- One mounting station on which the boltwork and the beam layer can be positioned, adjusted, clamped and angularly calibrated.

- The positioning of the frame work is achieved via two movable pressing beams

driven by motorized precision lead screws.

The width adjustment and the pressing (tension) of the elements are performed

motorized at the push of a button.

- Subdivided pressing beam 2 x approx. 6200 mm for simultaneous processing of

2 differently high wall elements.

- The pressing force is continuously adjustable via current relay.

- Through the spindle drive, absolutely parallel pressing of the wall elements is guaranteed, even when several small wall elements are produced on the station at the same time.

- The working height of the stations is approx. 700 mm

- 10 pcs system rack beams into which the plug bolts with a height of 135 mm can be inserted from the pressing beam,

for pressing wall elements as well as knee supports with a height

under approx. 2500 mm and for pressing cylinders for slanted wall constructions.

Stops:

- Stop at bottom with 20 stop plates, stop height 135 mm

- Lateral stop, left and right one detachable stop each, height 120 mm.

- Stop on the pressing beam, 20 plug bolts, height 135 mm,

spacing of the reception points for stop bolts, approx. 600 mm

- Additional stop on pressing beam front side, removable

- Mounting device up to 85° inclination angle

- Station front side each 1 electrical connection 230 V and a

compressed air connection for docking of hand tools.

Working area:

- Work surface length (element width): from min. 0 - max. 12,500 mm

- Work surface width (element height): from min. 550 - max. ~ 3,000 mm

- Working height/table height: approx. 690 - 700 mm

- Year of manufacture: 1997, partially overhauled in 2014

Perforated sheet surface:

- The station is technically fully panelled with perforated sheet D 17 mm as far as possible,

grid approx. 625 mm, for laying out individual frame constructions.

4 hand-press cylinders

- pneumatic

- Quick grid via grid bolts for perforated sheet plate

- Stroke 110 mm

- Die 130x120 mm

- Magnetic holder for adjustment of the cylinders

- Operation via hand lever valve

Colors:

- RAL 7030 stone gray

- RAL 1017 zinc yellow

Delivery/installation note:

(not included in purchase price, can be offered on request)

- The assembly table must be transported in two parts each approx. 6350 x 2650 mm

Specifications

| Manufacturer | Kein Hersteller |

| Condition | Used |

| Stock Number | 3304403 |

| Item location | D - North Rhine-Westphalia |