Belt and brush grinding machine VEN BRUSH HYBRID

Sold

Belt and brush grinding machine VEN BRUSH HYBRID

Location:North Rhine-Westphalia, Germany

Description

Year of manufacture 2011

SMOOTHING BRUSH MACHINE VEN BRUSH HYBRID

The machine is used for raw wood as well as intermediate varnish sanding of smooth and profiled workpieces, consisting of:

2 belt sanding units

- pressure lamella belt with felt and graphite for high durability

- ISD link pressure beam system with 22 mm workpiece recognition

and 44 mm pressure piece width

- workpiece controlled sanding belt blow-out

+ ISD link pressure beam system (sanding unit 1)

As ISA but additionally with

- separate adjustable pressure for the edge area

(higher or lower)

- optionally only on outer edge or outer and inner edges

- Longitudinal and transverse edges or only longitudinal edges adjustable optimal

air guidance for compliance with TRK values, dust-tested

- grooved rubber contact roller Ø 130 mm, 60 Shore

- program-controlled infeed of the contact roller

- program controlled grain size compensation

- ISA link pressure beam system with 22 mm workpiece recognition

and 22 mm pressure piece width.

- Counter-rotation

- workpiece-controlled oscillating sanding belt blowout

+ ISA link pressure beam system (sanding unit 2)

- pressure piece movable in longitudinal and transverse direction

- Punctiform pressure of the pressure piece

- universal lamella for all sanding operations

- tolerance compensation +/- 1 mm

ISA link pressure system:

General, Aggregates:

Sanding aggregates designed for single/two shift operation.

- Belt run-off switch coupled to the wide belts with oscillation

- automatic sanding belt length compensation

- abrasive belt scanning optically contactless and self-cleaning

on belt change side

- adjustment of oscillation on belt change side

- wear-free direct current braking

- Extraction hoods with optimum air flow for compliance with the

the TRK values,

ISA/ISD control

- High-resolution workpiece recognition in 22 mm grid

- Free loading of complex part shapes

- Multiple loading with small lateral distance

- Grinding intensity individually adjustable at all edges

- Grinding pressure adjustable via program

- Line control of the link pressure beams (feed-dependent)

- All settings via operator terminal (program-controlled)

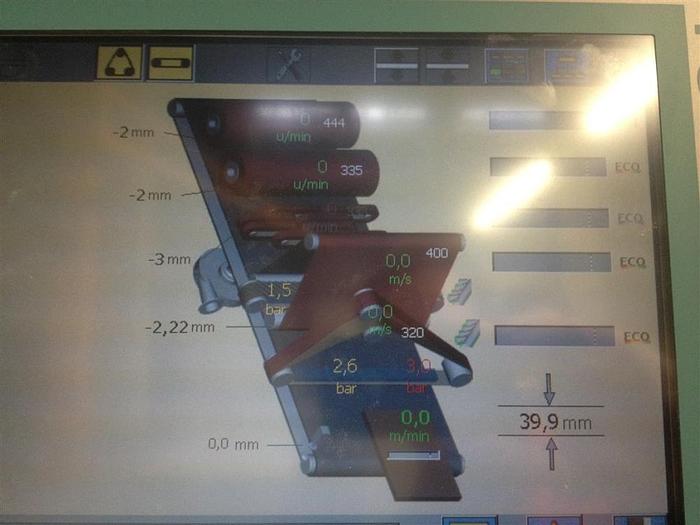

Control

All settings that have to be made for different grinding tasks can be made and saved directly via the touch control terminal.

Thus, all achieved sanding results are reproducible at any time.

Consisting of four counter-rotating brush segments for intensive smoothing of the workpiece profiles running transverse to the conveying direction. Designed as an exchangeable brush module.grinding speed infinitely adjustable.

The brushes are equipped with a quick-change system so that brushes with different fillings can be used within a few minutes.

The brush speed is changed via frequency converter and is shown on a display. The brush height can be adjusted individually for each of the brushes.

Machine frame

Heavy welded steel construction to support 2 sanding units. Electrical control cabinet integrated in the frame.

- Constant inlet height of 900 mm

- operating and belt change side on the right

- heavy height adjustment via lifting spindle gear

- transport table with transport belt in vacuum version and

1 vacuum blower 5,5 kW

- safety equipment according to CE standard

- electrical equipment according to VDE

- doors on both sides of the machine, on belt change side with

safety switches and inspection window to control the grinding-

belt oscillation

operating terminal "SIEMENS" MP 277

- graphic operator guidance via 10.5" color screen

- program memory with 300 program memory locations

- setting of all parameters via program

1 electrical control cabinet

With all necessary switching and fuse elements, motor protection switches, control lamps and main switch.

The switch cabinet contains all necessary contacts for interlocking the offered machine as well as machines from other manufacturers.

The switch cabinet is integrated into the machine.

Technical data:

Grinding unit1 12 kW

Sanding unit 2 15 kW

Extraction volume Dust extraction

(to be provided on site)

Specifications

| Year | 2011 |

| Condition | Used |

| Stock Number | 0,00 |

| Product code | 3306332 |

| Grinding unit 1 | Cross belt unit with |

| Grinding agregate 2 | Combination unit with |

| Grinding unit 3 | 1 Cross brush unit |

| Grinding unit 4+5 | 2 rotating brush units |

| Length | 4.370 mm |

| Working width | 1.300 mm |

| Working height | 900 mm |

| Belt speed | 1.6 - 16 m/s |

| Tape dimension 1 | 150 x 4.900 mm |

| Tape dimension 2 | 1.370 x 2.150 mm |

| Brush sets | 3 KW each |

| Brush length | 1.340 mm |

| Brush diameter | 350-440 mm |

| Brush speed | 50-450 rpm. |

| Drive power per brush | 3 kW |

| Total volume of dust-laden exhaust air | 10,500 m³/h |

| Electrical connection value | 69 kW |